Gentle cleaning for historic buildings like never before

Stone

Wood

Metal

Plastic

Testimonials

Explanatory video: How laser cleaning works

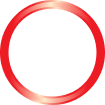

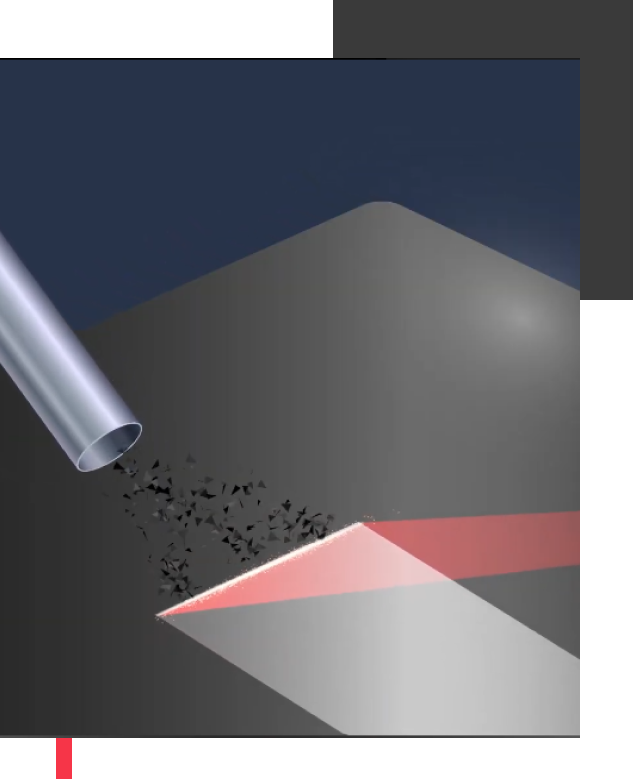

The cleaning laser generates “round pulses of light”. The pulses heat the top layer of grime for nanoseconds.

With a depth of only 0.01 to 0.5 mm per cleaning cycle, the layer removed is five times thinner than a human hair.

This means: The grime is removed micrometer by micrometer without damaging the underlying structure. Quick – quiet – easy on the environment.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Stone monuments at risk

Particulate matter, exhaust, soot, layers of pollution, algae, and vandalism cause severe damage to monuments, buildings, and statues over time.

The problem with cleaning: Chemical cleaning agents are often highly abrasive.

For sensitive materials, the only option is to remove deposits with …

… sand blasting

… dry ice blasting

… or a chemical sponge.

But be careful: In all of these procedures, the surface is mechanically treated. It is difficult to control how much is removed.

If parts of the structure come loose, valuable works of art will be damaged for good.

Fortunately, there is now a better method that is already being used by archaeologists in Egypt to uncover murals: laser cleaning.

Cleaning method comparison

Sand blasting

Efficiency

- around 2 m²/hour

Precision

- The sand acts as an abrasive. It roughens the surface and leaves it porous

User-friendliness

- Can only be performed using a mask and respiratory protection. The abrasives must be cleaned off the site afterwards

Energy consumption

- High energy consumption

Dry ice blasting

Efficiency

- 1-1.5 m²/hour

Precision

- This method is considered relatively gentle

User-friendliness

- Extreme noise levels. Protective suit required for workers. Operating the compressor and obtaining dry ice are logistically demanding

Energy consumption

- Very high energy consumption

Chemical sponge

Efficiency

- slow and exhausting

Precision

- The amount removed cannot be controlled

User-friendliness

- Difficult manual labor

Energy consumption

- No energy required (manual labor)

Laser cleaning

Efficiency

- 3-5 m²/hour

Precision

- Ultra-precise. The gentlest cleaning method on the market

User-friendliness

- Suitcase-sized machine, low noise, only protective goggles required

Energy consumption

- Consumes no more energy than a light bulb

Sand blasting

Dry ice blasting

Chemical sponge

Laser cleaning

Efficiency

- around 2 m²/hour

- 1-1.5 m²/hour

- slow and exhausting

- 3-5 m²/hour

Precision

- The sand acts as an abrasive. It roughens the surface and leaves it porous

- This method is considered relatively gentle

- The amount removed cannot be controlled

- Ultra-precise. The gentlest cleaning method on the market

User-friendliness

- Can only be performed using a mask and respiratory protection. The abrasives must be cleaned off the site afterwards

- Extreme noise levels. Protective suit required for workers. Operating the compressor and obtaining dry ice are logistically demanding

- Difficult manual labor

- Suitcase-sized machine, low noise, only protective goggles required

Energy consumption

- High energy consumption

- Very high energy consumption

- No energy required (manual labor)

- Consumes no more energy than a light bulb

How laser cleaning works

How it works in

5 simple steps:

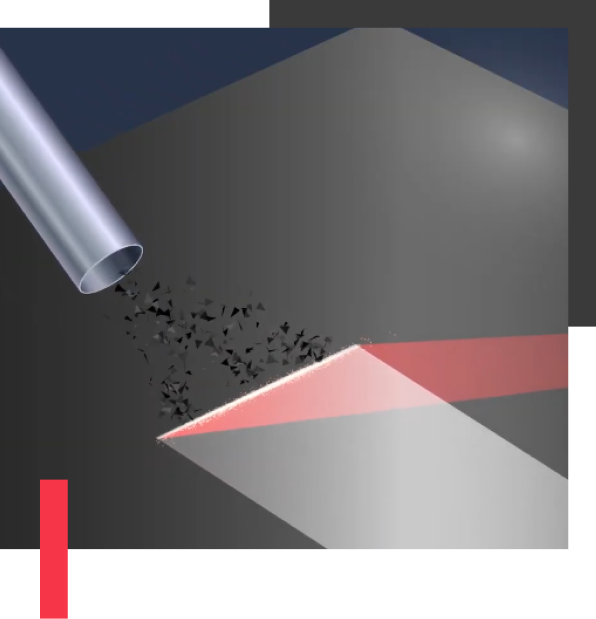

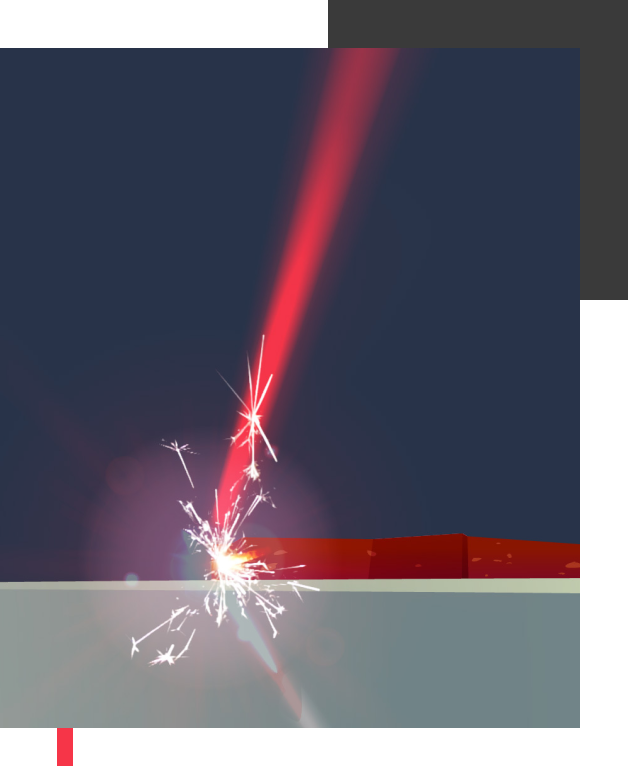

Step 1

The laser shoots “round pulses of light” at the surface

Step 2

The grime absorbs the light energy and heats up for a few nanoseconds

Step 3

The grime evaporates while the surface becomes slightly warmer

Step 4

To prevent the fumes from reattaching, they are immediately vacuumed away.

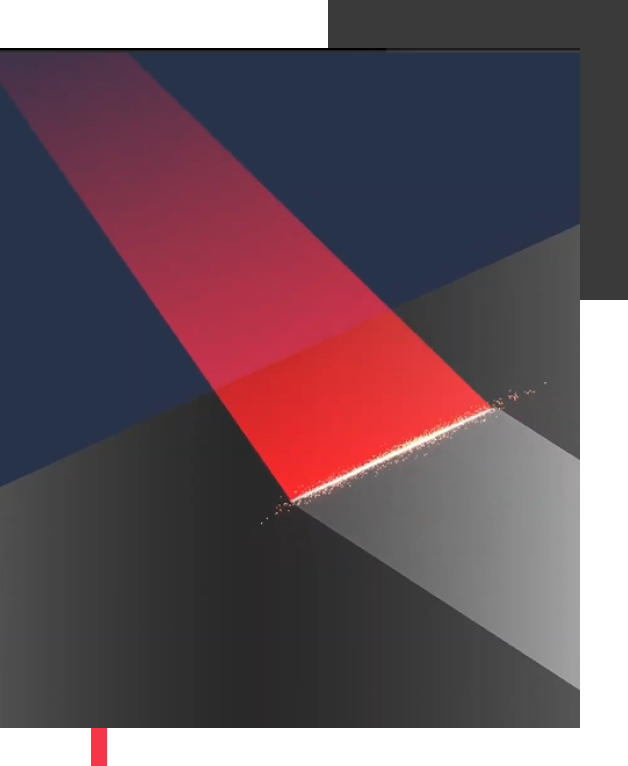

Step 5

Result: A clean, smooth, and undamaged surface.

Step 1

The laser shoots “round pulses of light” at the surface

Step 2

The grime absorbs the light energy and heats up for a few nanoseconds

Step 3

The grime evaporates while the surface becomes slightly warmer

Step 4

To prevent the fumes from reattaching, they are immediately vacuumed away.

Step 5

Result: A clean, smooth, and undamaged surface.

Novosan Laser Clean

Pioneers of laser cleaning in Switzerland and Europe

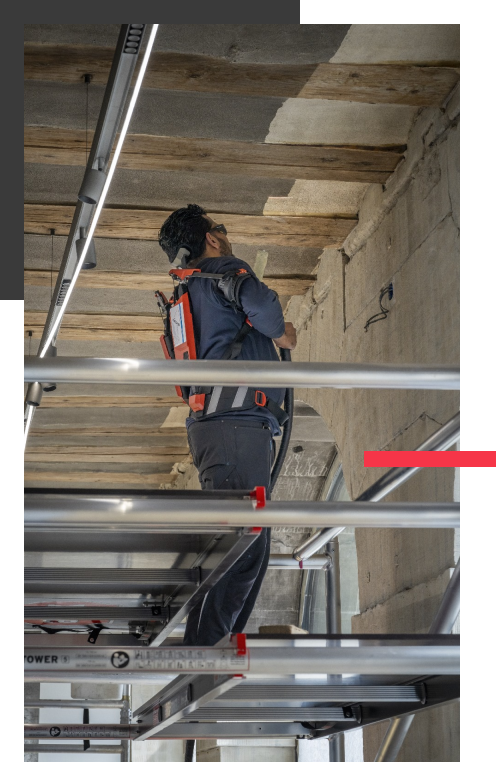

The Novosan Laser Clean team removes grime from historic buildings without the use of any chemicals, with a minimal carbon footprint, and without damaging stonework. Depending on the level of staining, we clean an average of 3 m³ per hour. This is significantly faster than other methods.

Our innovation and commitment to sustainability and safety were recognised by the renowned London-based magazine Business Worldwide, which named us one of the “20 Most Innovative Companies to Watch, 2024”.

The cleaning lasers only affect layers that are 5 times thinner than a hair.

That means: Unless aimed at the eyes, the technology is relatively harmless for human beings.

This is why we equip our employees (and you) with safety glasses and fence off the cleaning area with protective walls.

The personal protective equipment (PPE) is much simpler than what is required for other cleaning processes, like sand- or dry-ice blasting.

As the first provider in Switzerland, we are now training other providers to use the Novosan safety concept.

The collaboration process

Live on-site demonstration

We will provide an in-person demonstration on how we use laser cleaning to remove different types of grime – including soot, graffiti, and particulate matter. Don’t worry: We won’t test it directly on your building. We bring a variety of sample materials with us.

Inspection of the structure on site

Have you decided that laser cleaning is the right approach? We will check what type of staining is involved, what the surface is like, and whether our cleaning process is suitable for your situation. And if it that all checks out? We’ll gladly laser a small sample area of your structure free of charge. If you are satisfied, we will send you a quote.

Cleaning

Have you decided that working with us is the right choice? If so, we will schedule an appointment for cleaning. Our trained technicians will bring everything that they need. The only thing you have to provide is a standard power outlet.

What you can expect in the live demonstration

About us

About us

Novosan has specialized in building cleaning and renovation for decades.

When Martin Schweizer, a mechanical engineer and economist with over 20 years of experience, took over the affiliated company Novosan in 2022, he breathed new life into the company.

He had already encountered laser technology as a student. Whether for welding, cutting sheet metal, measuring, engraving, optical laser technology or archaeology, lasers are used wherever extreme precision is required.

And it’s not only in engineering that lasers are indispensable – the technology has also been used in medicine for decades.

But there is one area where lasers are not yet in use, even though the work requires the same level of precision as in medicine and engineering: building cleaning.

So Martin Schweizer came up with the idea of modifying a standard laser for use in cleaning buildings and monuments made of wood, stone, and synthetic materials. After thorough research, countless tests, and a long development period, he and his team have achieved that goal.

Novosan Laser Clean AG, the first provider of laser cleaning equipment in Switzerland, has been recognised by London-based magazine Business Worldwide as one of the “20 Most Innovative Companies to Watch, 2024”.

Laser cleaning: Burgdorf Castle

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Burgdorf Castle – Switzerland

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

FAQ

Can I use it to clean off any kind of dirt or grime?

We can clean almost anything with our laser. Soot, particulate matter, exhaust, algae, spray paint (graffiti), mold, and much more. Since our laser is extremely gentle, we have even used it to clean Styrofoam without damaging the surface.

However, as a general rule, the tougher the staining, the more intensively it needs to be lasered. For particularly sensitive surfaces such as wood, the result may not meet the normal quality standards of Novosan Laser Clean because too much energy has to be used for cleaning to avoid leaving any trace on the wood.

To rule this out, we always personally inspect your building first and check whether cleaning is possible for your situation.

How much energy is needed for laser cleaning?

How much does the laser remove?

How does laser cleaning work?

How quickly does the laser clean?

What other areas can laser cleaning be used for?